In the complex world of oil and gas extraction, understanding the flow of fluids through rock formations—known as permeability—is a cornerstone of maximizing reservoir productivity and recovery rates.

CNPS, a leader in providing innovative solutions to the oil and gas industry, sheds light on the pivotal role of permeability in oil extraction, offering insights into methods for its measurement and enhancement.

For expert advice and state-of-the-art solutions in enhancing permeability, including our specialization in reinforced thermoplastic pipes (RTP) and comprehensive oilfield services and equipment, CNPS stands as your go-to resource.

The Essence of Permeability in Oil Extraction

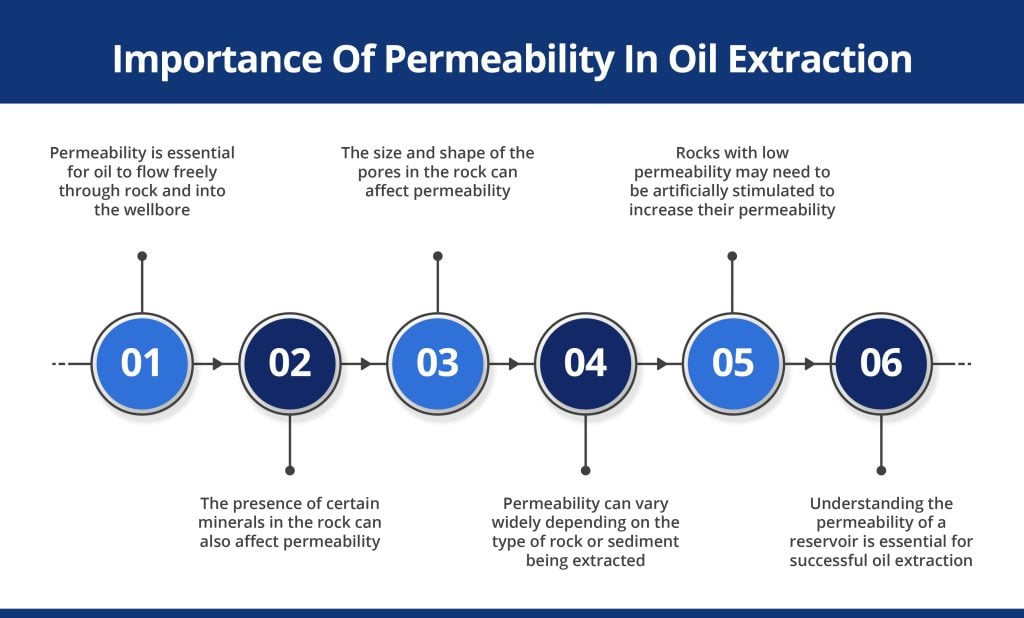

Permeability is the characteristic of a rock that allows fluids to pass through its pores or cracks. In oil and gas production, the ease with which oil can move through a reservoir’s rock formations directly impacts the efficiency of extraction processes and the ultimate recovery rates of a well. Not all reservoirs are created equal; some are naturally more permeable than others, enabling easier fluid flow and more efficient oil recovery.

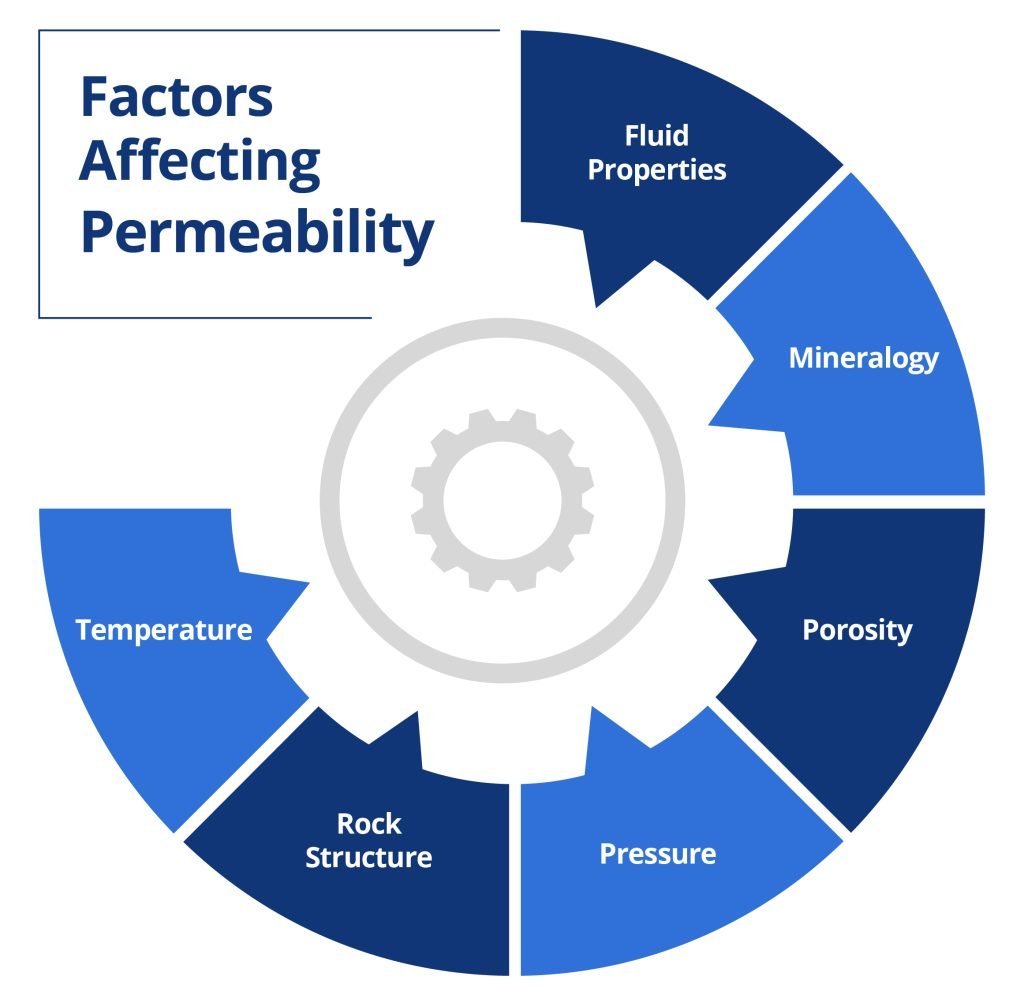

However, permeability is not a constant value. It can vary significantly across different areas of a reservoir, influenced by factors such as rock type, sedimentary layering, and the presence of natural fractures. This variability presents challenges and opportunities in the strategic development of oil fields.

Understanding these variations is crucial for developing effective extraction strategies, including the selection of appropriate drilling locations and the application of enhanced oil recovery (EOR) techniques that can alter reservoir properties to improve oil flow.

The degree of permeability is influenced by both the size of the pores in the rock formation and the connectivity of these pores. Highly permeable reservoirs allow for the free flow of oil, reducing the need for intensive EOR methods.

In contrast, reservoirs with low permeability may require the application of techniques such as hydraulic fracturing or acid stimulation to enhance permeability and stimulate production.

Moreover, the measurement and enhancement of permeability are critical components of reservoir engineering, requiring sophisticated technology and specialized knowledge. Advanced imaging techniques and reservoir simulation models play an integral role in assessing permeability and designing interventions to optimize oil recovery.

These technological advancements, coupled with an in-depth understanding of geological formations, enable oil and gas companies to maximize the productive capacity of their reservoirs, ensuring sustainable and efficient extraction practices.

In navigating the complexities of permeability and its impact on oil extraction, CNPS offers a wealth of expertise and innovative solutions, from advanced materials like FRP and GRE pipes that support EOR operations to state-of-the-art oilfield equipment designed to enhance the productivity of low-permeability reservoirs.

By partnering with CNPS, industry professionals can leverage cutting-edge technology and engineering excellence to unlock the full potential of their oil and gas assets.

Measuring Permeability: A Key to Optimized Production

Accurate measurement of permeability is crucial for the oil and gas industry to make informed decisions regarding well placement, production strategies, and enhanced recovery techniques.

Several sophisticated methods are employed to gauge permeability, reflecting the complex nature of subsurface environments. These include:

- Core Sampling and Analysis: The most direct method involves extracting rock samples during drilling and measuring their permeability in a laboratory setting. This approach provides precise data but is time-consuming and costly.

- Well Testing: Techniques such as pressure transient testing allow for the estimation of permeability based on the flow of fluids into or out of the well. This method offers insights into the permeability of the reservoir near the wellbore.

- Advanced Imaging Techniques: Technologies like micro-CT scanning offer non-invasive ways to understand the pore structure of rock samples and estimate their permeability. These methods are particularly useful for analyzing tight rock formations where traditional methods may not be effective.

To enhance permeability and, consequently, oil recovery, several innovative approaches are utilized:

- Hydraulic Fracturing: By creating fractures in the rock, hydraulic fracturing significantly increases permeability, allowing oil to flow more freely to the production wells. This method is especially effective in tight formations such as shale.

- Acidizing: The process involves injecting acid into the reservoir to dissolve carbonate rocks or remove debris from the pores, thereby improving the permeability of the formation.

- Thermal Recovery Methods: Techniques such as steam injection heat the reservoir, reducing the viscosity of heavy oils and improving their mobility. This method is particularly useful in heavy oil sands.

At CNPS, we recognize the intricacies of measuring and enhancing permeability. Our portfolio includes oilfield services and equipment designed to support these critical activities. From advanced sensing technologies that provide real-time data on reservoir conditions to durable and corrosion-resistant materials like FRP and GRE pipes, we equip our clients with the necessary tools to navigate the challenges of reservoir development effectively.

Incorporating these methods and technologies into your operations can lead to a more accurate understanding of reservoir characteristics and enable the implementation of strategies to maximize oil recovery.

With a commitment to innovation and sustainability, CNPS is your ideal partner in unlocking the full potential of oil and gas reservoirs.

Enhancing Permeability for Increased Oil Recovery

Recognizing the importance of permeability, the industry employs various techniques to improve it, thereby enhancing oil flow and recovery.

Hydraulic fracturing, for example, creates new fractures in the rock or widens existing ones, improving permeability in tight formations. Acidizing, another common method, involves injecting acid into the reservoir to dissolve rock materials and open up flow paths for oil.

Additionally, the use of innovative materials and technologies, such as fiberglass pipes supplied by leading fiberglass pipe manufacturers like CNPS, plays a crucial role in supporting enhanced oil recovery operations.

These materials are chosen for their durability, corrosion resistance, and ability to withstand the harsh chemical environments often involved in permeability enhancement treatments.

Fiberglass pipes, for example, offer significant advantages over traditional materials due to their lighter weight, ease of installation, and lower maintenance requirements, making them an ideal choice for both onshore and offshore applications.

Other techniques for enhancing permeability include thermal recovery, which involves the introduction of heat to reduce the viscosity of heavy crude oils, and gas injection, where gas is injected into the reservoir to maintain pressure and improve oil displacement.

Each of these methods is designed to address specific challenges associated with oil extraction, and their application can significantly impact the economic and operational viability of oil and gas projects.

Understanding and improving permeability is a multidisciplinary effort that encompasses geology, engineering, and material science. By integrating advanced measurement techniques, innovative materials, and specialized recovery methods, the oil and gas industry continues to make strides in optimizing production from existing fields and unlocking new resources.

At CNPS, we are committed to advancing these efforts by providing our clients with the expertise and technologies needed to enhance permeability and maximize recovery, ensuring the sustainable and efficient development of oil and gas resources.

The Role of CNPS in Advancing Permeability Solutions

At CNPS, we understand the critical role permeability plays in the success of oil extraction projects. Our offerings in oilfield services and equipment, including advanced materials like FRP and GRP pipes, are designed to support the industry’s efforts to measure, understand, and improve permeability. With a focus on renewable and sustainable energy solutions, we are committed to providing our clients with the tools and expertise needed to navigate the complexities of reservoir development and achieve optimized production outcomes.

Partner with CNPS for Your Permeability Enhancement Needs

Managing the challenges of permeability in oil extraction demands expertise and access to innovative solutions. With CNPS, you gain a partner equipped with extensive experience and cutting-edge technologies, from mud logging sensors to fiberglass solutions, aimed at enhancing the productivity of your oil and gas operations.

For more information on how we can assist in optimizing your projects through improved permeability solutions, reach out to CNPS at [email protected] or call +86 183 546 39099. Let us empower you with the knowledge and technology to unlock the full potential of your reservoirs, setting the stage for a more efficient and productive future in the oil and gas industry.